This ariticle is a short introduction ‘Theory of Constraints. This can help a lot to bring effiecieny in any work/process.

Have a look at the chain in the picture given above -we all can see a weak link .

And we all know that to improve the strength of the chain , one needs to first strengthen this weak link !

This is quite obvious !

Let me ask you a question here .

Can we strengthen this chain by increasing strength of other links but without doing any thing about the weak link ?

Answer would be again obvious here – strengthening the other links would never increase the overall strength of the chain, because the weakest link still exists.

No chain can ever be stronger than it’s weakest link. That is why it is said that no team is stringer than its weakest member .

This also means that processes, teams, organizations are vulnerable because of their weakest person or part as they can always damage or break them or at least adversely affect the performance or outcome.

This all sounds so simple here but most of the people tend to ignore it every day’s environments – in their teams or organizations and even in their own lives.

This is obvious when you think about the example of the chain and its links, but for some reason we don’t treat the world this way.

When a system doesn’t work, we get overwhelmed and struggle. We try to focus on every part of the struggling system rather than finding the weakest link and spending all our energy on improving it.

Hence understanding it rightly can have huge implications on success or productivity of a process, an organization , a team or even for an individual.

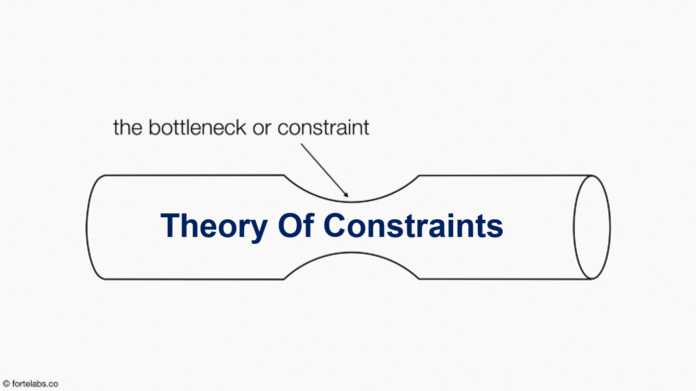

Here let me introduce to the Theory of Constraint (TOC).

TOC is an overall management philosophy introduced by Eliyahu M. Goldratt in his 1984 book titled The Goal .

The Core Idea Of TOC – Every process has a constraint (bottleneck, weakest link) and focusing improvement efforts and energy on that constraint is the fastest and the most effective path to improve performance /productivity.

This methodology involves 3 steps :

1) Identifying the most important limiting factor (i.e. constraint) that stands in the way of achieving a goal. This constraint is also known as bottleneck or weakest-link.

2) Then systematically improving that constraint until it is no longer the limiting factor.

3) Keep repeating this process . Once you have worked upon the first constraint, then try to find the next constraint and work upon it . Keep working , continuously repeating this process until you get where you want.

For example, on individual level ,let’s say you’re trying to pursue a hobby but you can’t get yourself to start, or you’ve given up several times after starting .

Try to identify your underlying inputs:

- Time

- Motivation

- Knowledge of how to move forward

Ask yourself: By doubling which of these inputs could make you start and stick with it ?

Let’s say it knowledge of how to move forward !

Increase that input first. Try to learn about it more and more from others who are already in that hobby .Ask them

Then, still if you find yourself stuck once after starting, repeat the process.

Perhaps next time your time or motivation will be the constraint.

TOC (Theory of Constraints) is equally important in business.

For example, ask if the reason you’re not getting more sales is because one of these inputs is under-optimized compared to the others:

- Distribution

- Product Packaging

- Product quality

- Marketing

- Pricing

Find your bottleneck, work on that continuously, and continuously repeat this process until you get where you want.

At any given time, one thing will be holding you back.

Your job is to remember to look for it.

The Thinking Processes

The Theory of Constraints talks about a problem solving methodology called the Thinking Processes.

These are used to answer the following 3 questions

- Constraint : What needs to be changed?

- Replacement :What should it be changed to?

- Execution Area :What actions will cause the change?

If you want to learn more , you can check this link

If you want learn more about one more tool ( different than Theory of Constraints) for prioritizing your work and improve the process ,please click on this link ‘Ice Model’.

12 claps

Simple and effective explanation on TOC … Thanks